How does a CO2 laser cutting machine work?

Principles of Laser Cutting

The Carbon Dioxide Laser (CO2 laser) was one of the first gas lasers ever invented. Developed in 1964, it is still widely used today for creating various products and applications.

CO2 lasers produce an infrared light beam. This beam is powered by the gas contained in the laser tube. The gas mixture typically consists of:

- Carbon Dioxide (CO2): Approximately 10-20%

- Nitrogen (N2): Approximately 10-20%

- Hydrogen (H2) and/or Xenon (Xe): A small percentage (usually used in sealed tubes)

- Helium (He): The remaining portion of the gas mixture.

The specific proportions of the gas mixture vary depending on the particular cutting or engraving application. CO2 laser cutting machines, which operate in the infrared spectrum, require special materials for their construction. Typically, the mirrors are silver-coated, while the lenses are made of germanium or zinc selenide.

CO2 laser cutting machines are often used in industrial applications for cutting and welding, whereas lower-power lasers are commonly employed for engraving.

CO2 LASER CUTTING MACHINES – MEDIUM POWER

For WOOD, PLASTIC, PLEXIGLASS, METAL, CARDBOARD, FABRIC, RUBBER.

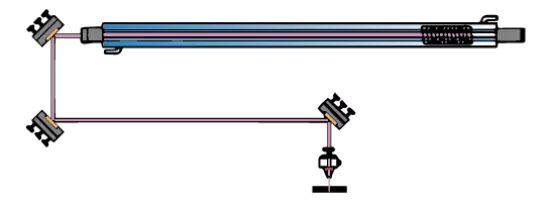

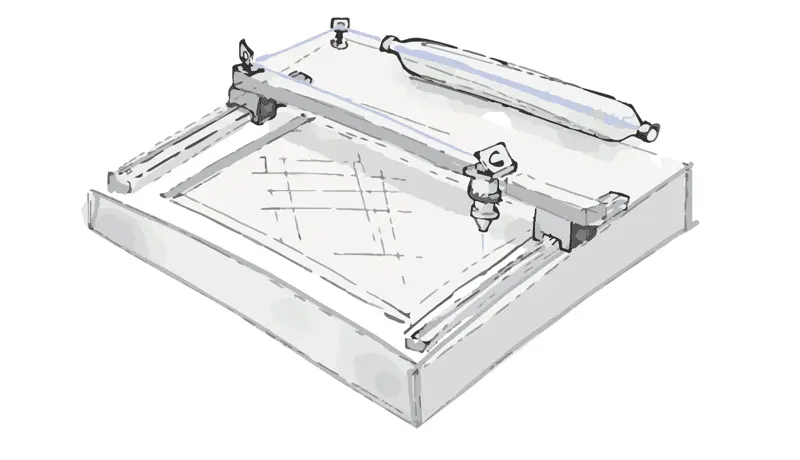

CO2 laser cutting with CNC technology operates by transmitting the laser beam from the tube to the material through a system of mirrors (see figure).

The laser generation process involves heating the tube, which is cooled using distilled water. The tube generates a laser beam that reflects off mirrors and passes through a lens before reaching the cutting surface. Proper adjustment of the distance between the lens and the material is crucial for achieving precise cuts. Additionally, a jet of compressed air is directed at the cutting point to aid the process.

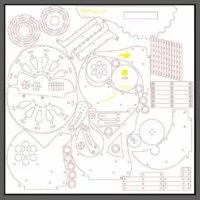

The entire cutting or engraving process occurs in a vacuum environment maintained by suction pumps. The machine is connected to a PC with dedicated software that converts vector designs into cutting or engraving commands. Each vector is assigned specific settings for power and movement speed of the laser head, which vary depending on the thickness and nature of the material.

It is evident that the higher the laser’s power, the greater the maximum thickness and the variety of materials it can cut.

Do you have a project to laser cut?

ONLINE LASER CUTTING AND ENGRAVING SERVICE FROM FILE

You will immediately be able to see Preview, Dimensions, Materials, Costs and Delivery Times.

YOU MAY ALSO BE INTERESTED IN…