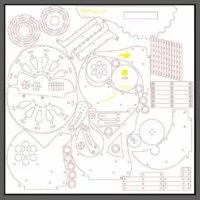

What operations can I perform with laser cutting?

With CO2 laser cutting, there are three main types of operations you can perform

Description

CO2 laser cutting is a widely used and versatile processing technology that allows for high-precision results in various applications. Specifically, with CO2 laser cutting, three types of operations can be performed: cutting, linear engraving, and areal engraving.

Cutting involves the operation of cutting the material in sheets according to the designed path. Thanks to the precision of the laser, it is possible to achieve perfectly straight and clean edges, without the need for further finishing.

Linear engraving, on the other hand, is a surface treatment that follows the designed path, creating a mark on the material’s surface. This type of operation can be used to create designs or text without necessarily cutting through the material. Scratching is particularly suitable for making plaques, labels, or decorations on materials like wood, plexiglass, or steel.

Finally, areal engraving is a type of operation that involves marking an area of the material with “heat.” Unlike scratching, engraving involves creating a filled area, rather than just simple contours. This type of operation is especially suitable for making plaques, medals, and decorations on materials such as wood, steel, or plastic.

CUTTING

Cuts the material according to the designed path.

LINEAR ENGRAVING

Creates a surface mark following the designed path

AREAL ENGRAVING

Burns the designed areas into the material

In any case, it is important to specify that in order to achieve high precision with CO2 laser cutting, it is necessary to differentiate the colors of the lines in the file or design, associating them with the different operations.

This way, the laser will be able to recognize the various operations to be performed, ensuring maximum efficiency and precision in processing the material.

In conclusion, CO2 laser cutting is a very versatile and reliable technology that allows for the execution of various types of operations on a wide range of materials. Thanks to the precision of the laser, high-quality results and finishes can be achieved without the need for further processing or finishing.

Do you have a project to laser cut?

ONLINE LASER CUTTING AND ENGRAVING SERVICE FROM FILE

You will immediately be able to see Preview, Dimensions, Materials, Costs and Delivery Times.

Adhesive on the Back

A strong double-sided adhesive will be applied before cutting the parts.

This extra option has been developed to offer our customers a complete and ready-to-use solution, ideal for a wide range of applications, both indoor and outdoor.

Why choose the Double-Sided Adhesive on the Back?

Our double-sided adhesive service transforms your projects into finished adhesive products, ready to be applied immediately after cutting. This not only saves time in the finishing process but also ensures perfect adhesion for every application. Whether it’s for signage, wall decorations, stencils, or any other element requiring secure and long-lasting adhesion, our adhesive is the optimal solution.

Advantages:

- Convenience: Your laser-cut pieces will arrive with adhesive already applied, eliminating the need for post-cut manual application.

- Durability: We select excellent adhesives for both indoor and outdoor use, ensuring strong and long-lasting hold over time.

- Precision: The adhesive is applied before laser cutting, ensuring perfect coverage with no smudges.

- Versatility: Our service is suitable for all materials and thicknesses available in the configurator, offering customized solutions for every project.

Sanding

Valid only for wooden materials.

It can be selected to obtain a product that is already ready to be used.